Augmented Reach, Same Premium Quality

Known for its commitment to excellence, MyCigarsASAP.com supplies a curated collection of premium cigars from renowned brands in the industry. By broadening its reach to West Hollywood, the company continues to offer immediate availability of a wide range of luxury cigars, sustaining the same rigorous quality control standards that have made it a reliable choice among cigar enthusiasts.

Cigar Delivery West Hollywood

CALL (800) 654-7959

Customers in West Hollywood may choose from renowned brands like: • Arturo Fuente – Providing a extensive selection of finely made cigars. • Montecristo – Famous for its refined, equilibrated concoctions that suit varied tastes. • Cohiba – Recognized globally for delivering a full-bodied, potent smoking experience. • Davidoff – A symbol of sophistication, providing cigars of unequaled reliability and excellence. • My Father's Cigars – Supplying full-flavored, rich tastes that are inspired by Cuban cigar heritage. • Ashton – Esteemed for its refined, delicate flavor, made from the premium tobaccos from the Dominican Republic. • Padron – Celebrated for its bold tastes and masterful artistry, including the highly desired 1964 Anniversary Series. • Romeo y Julieta – A staple choice celebrated for its balanced flavors and uniform quality.

This diverse selection assures that MyCigarsASAP.com addresses a diverse set of preferences, with cigars supplied by well-known regions like Nicaragua, the Dominican Republic, and Honduras.

Attention to Freshness and Perfection

Quality is at the center of MyCigarsASAP.com’s functions. To make certain every cigar arrives in ideal condition, the company implements meticulous quality control standards, including precisely controlled storage and handpicked inventory. Every order is managed carefully, confirming that the cigars are supplied fresh and flavorful. Besides, their team of cigar professionals is on hand to offer customized advice, providing a personalized and informative experience to every customer.

Immediate and Convenient Delivery to West Hollywood

Through this latest increase in service, MyCigarsASAP.com establishes its role as a premier fast premium cigar delivery service locally. Whether for a surprise party, a organized gathering, or a quiet night of unwinding, inhabitants in West Hollywood can now take pleasure in rapid cigar deliveries within 30 to 60 minutes of order placement. This fast service introduces a new level of convenience to West Hollywood’s cigar community.

Cigar Delivery West Hollywood

CALL (800) 654-7959

About MyCigarsASAP.com

MyCigarsASAP.com is a California-based cigar delivery service passionate about delivering quick, steady access to a fine collection of cigars. With a dedication to quality, freshness, and personalized service, the company has established itself as a reputable source for cigar connoisseurs region-wide. Now, with augmented service to West Hollywood, MyCigarsASAP.com stays ahead in supplying luxury cigars with speed and precision.

For more facts or to set up an order for speedy delivery, call (800) 654-7959.

Cigar Genesis and History: A Passage Through Ages

Cigars, often aligned with extravagance, practice, and skill, carry a extensive past tracing back hundreds of years. The transformation of cigars demonstrates the convergence of peoples, discovery, and mercantile trade. This composition probes the fascinating genesis and heritage of cigars, mapping their passage from indigenous practices in the Americas to growing into a global icon of class.

The Old Inception: Cigars in Pre-Columbian Cultures Cigars have their primitive origins in the native civilizations of the Americas. Prehistoric communities, including the Mayans, Aztecs, and Taínos, are understood to have partaken of rolled tobacco leaves. Excavation evidence display illustrations of Mayans enjoying on terracotta pieces tracing back to not less than the 10th century. The label “cigar” apparently evolves from the Mayan phrase “sikar,” which denotes to smoke.

In these old societies, tobacco was not only a casual product but also held sacred significance. Shamans and tribal leaders partook of tobacco during holy traditions, holding it allowed them to engage with the supernatural world. Tobacco was also used therapeutically, offering mitigation for various maladies, such as aches and digestive issues.

Tobacco’s Inception to Europe: Columbus and the New World The European legacy of cigars started with Christopher Columbus’s appearance in the Americas in 1492. His crew discovered native people puffing wraps of dried tobacco greens, an unknown practice that engaged them. Columbus and his men carried bits back to Spain, marking the inception of Europe’s relationship with tobacco.

The practice of using quickly spread across Europe. Spaniards welcomed it first, and by the 16th century, tobacco use turned into popular among European gentry. Early cigars were basic against modern versions, but their charm spread to Italy, Portugal, and France. Tobacco was also viewed as an elixir, believed to alleviate a host of conditions from infections to fatigue.

Cuban Influence: Birthplace of the Modern Cigar Cuba’s place in cigar past is fundamental, turning tobacco from a indigenous commodity into a planetary phenomenon. In the 17th century, Cuba became the heart of cigar generation due to its excellent climate and fertile soil, particularly in the Vuelta Abajo region. Cuban cigars quickly achieved a reputation for peerless quality and artistry.

By the 1800s, the Cuban cigar industry was expanding, and the term “Havana cigar” was synonymous with excellence. Master artisans, known as torcedores, assembled cigars by hand, perfecting techniques that persist largely unchanged today. Many of the world’s most legendary cigar brands, such as Montecristo, Cohiba, and Romeo y Julieta, owe their origins to this era.

The Enlargement to North America and Europe The need for cigar s grew beyond Cuba’s borders by the 18th and 19th centuries. Tobacco plantations started appearing in other Caribbean islands, such as the Dominican Republic and Jamaica, as well as parts of Central America, including Honduras and Nicaragua. These regions continue to be cigar strongholds today, each adding singular characteristics to their products.

In Europe, Spain and the Netherlands were notable consumers and producers of cigars. The Dutch set up a solid cigar industry, importing Cuban tobacco and mixing it with local leaves to generate individual styles. Meanwhile, cigar consumption in the United States became aligned with status and masculinity. The rise of industrialization saw cigar factories grow across the U.S., particularly in Florida, where Cuban immigrants introduced their craftsmanship and traditions.

Cigars and Social Status: From Aristocracy to the Everyday Man Throughout background, cigars have been closely connected to status, wealth, and celebration. By the 19th century, cigars were a staple among European and American aristocrats. Monarchs Bonuses such as King Edward VII of England were well-known cigar devotees, further enhancing their popularity among the elite.

In the United States, cigars became related to political power and business success. Industrial magnates like Andrew Carnegie and John D. Rockefeller were often pictured consuming cigars, reinforcing their image as symbols of wealth. Prominent figures such as Winston Churchill famously espoused cigars, adding to their prestige.

However, cigars were not confined to the upper class. The growth of the cigar industry led to the production of budget-friendly options, making cigars available to the working class. Cigar clubs and lounges surfaced, offering places where people from all walks of life could partake in a smoke.

The Cuban Embargo and the Rise of New Markets The Cuban cigar industry faced a major turn in 1962 when the U.S. government, under President John F. Kennedy, applied a trade embargo on Cuba. Cuban cigars, previously a mainstay among American cigar devotees, became illegal in the U.S., creating both shortage and enigma around them. As a result, many Cuban cigar makers fled to neighboring countries like the Dominican Republic, Nicaragua, and Honduras, where they continued their art using Cuban-seed tobacco.

This geopolitical upheaval opened new markets and added to the rise of premium cigars outside Cuba. Today, cigars from these regions are esteemed for their quality, matching Cuban cigars in flavor, construction, and diversity.

Cigars in Popular Culture and Cinema Cigars have secured their place in popular culture, often standing for power, victory, and sophistication. Hollywood embraced the cigar as an icon, featuring it prominently in films. Characters like Tony Montana in Scarface and Winston Churchill in The Darkest Hour continue the relationship between cigars and authority.

Moreover, cigars are a essential at celebrations, marking occasions such as weddings, business deals, and the birth of children. Cigar lounges and clubs continue to serve as venues for socializing and networking, enhancing their cultural relevance.

The Modern Cigar Renaissance The late 20th and early 21st centuries have recorded a resurgence of cigar culture. The 1990s “Cigar Boom” in the U.S. saw a renewed interest in premium cigars, with new enthusiasts joining the scene. Skill, diversity in blends, and custom techniques have advanced the modern cigar renaissance.

Craft cigar brands have earned popularity, offering singular blends that appeal to a growing demographic of younger smokers. Additionally, the rise of cigar lounges and online cigar shops has made it simpler for consumers to discover different varieties from around the world. Events like Cigar Aficionado’s Big Smoke further show the lasting attraction of cigars in contemporary culture.

Cigars and Sustainability: The Future of the Industry As the cigar industry develops, sustainability has become a priority. Environmental factors, including climate change and deforestation, impact tobacco cultivation. Many cigar manufacturers are embracing eco-friendly practices by using sustainable farming methods and supporting reforestation efforts.

Fair labor practices are also increasing, with companies assuring fair wages and safe working conditions for the farmers and artisans involved in cigar production. The priority on sustainability intends to protect the industry’s legacy while meeting the expectations of socially conscious consumers.

Conclusion: A Legacy of Tradition and Craftsmanship From the sacred customs of indigenous tribes to the sumptuous lounges of today, cigars have advanced a long and storied path. Each inhalation of a premium cigar encapsulates with it the legacy of generations of workmanship, tradition, and cultural significance. Whether savored by royalty, industrial tycoons, or modern-day fans, cigars continue to signify more than just tobacco—they encapsulate a lifestyle, a celebration, and a link to history.

As the world of cigars evolves, one thing continues constant: the attraction of sitting back, lighting up, and savoring the ingenious combination of tradition and innovation cloaked in each leaf.

The Cigar Assembly Method: A Trip from Yesteryears to Now

The Cigar Manufacturing Process: An Journey from Past to Present

Introduction

One cigar, one timeless symbol of grandeur and refinement, has a single rich history that covers centuries and continents. From its early origins among first peoples to its modern incarnation as an global industry, the process of crafting a cigar is an blend of mastery, technology, and tradition. This article investigates the intricate journey of cigar manufacturing, comparing the methods of the past with those of today, and showcasing how innovation and heritage blend in this fascinating craft.

I. Historical Overview of Cigar Manufacturing

A. Early Origins of Cigars

The history of cigars reaches back to the indigenous peoples of the Caribbean and Mesoamerica, who tended tobacco and used it in religious and medicinal practices. When Christopher Columbus arrived in the New World in 1492, he and his crew saw the native Taíno people of Cuba and Hispaniola making and smoking dried tobacco leaves. This practice amazed the Europeans, who brought tobacco back to the Old World, where it quickly earned popularity.

B. Traditional Cigar-Making Techniques

1. Tobacco Cultivation

In the early days, tobacco cultivation was a manual and labor-intensive process. Farmers used natural cycles and traditional knowledge to grow tobacco plants. The seeds were sown by hand, and the plants required meticulous care to thrive.

2. Leaf Selection and Fermentation

After harvesting, the tobacco leaves went through a natural air-curing process. They were placed in curing barns to dry slowly, facilitating the chlorophyll to break down and the leaves to develop their characteristic brown color. Fermentation subsequently occurred, where the leaves were layered in piles called pilones. The natural heat generated by microbial activity decreased harshness and elevated the rich flavors.

3. Rolling Methods

Cigar rolling was an craft inherited through generations. Skilled artisans, known as torcedores, shaped cigars entirely by hand. They opted for filler leaves, tied them with a binder leaf, and coated the bunch with a high-quality wrapper leaf. This meticulous process required precision and an eye for quality.

C. The Role of Cuban Cigar Tradition

Cuba became synonymous with premium cigars due to its ideal climate and soil conditions, particularly in the Vuelta Abajo region. The country's cigar-making techniques set the standard for quality and craftsmanship. Cuban cigars were in high demand, and the methods developed there influenced cigar production worldwide.

II. Modern Cigar Manufacturing Process

A. Advances in Tobacco Cultivation

1. Genetic Selection

Modern agriculture has introduced genetic selection to refine tobacco plant qualities. Scientists and farmers join forces to develop tobacco strains resistant to diseases and pests, and with desired flavor profiles. This yields more consistent and high-quality crops.

2. Modern Farming Techniques

Today, tobacco farming uses advanced irrigation systems, soil management, and crop rotation to maximize yield and quality. Precision agriculture technologies, such as GPS mapping and drones, facilitate monitor plant health and optimize resource use.

B. Leaf Processing Today

1. Fermentation Methods

While the fundamental principles of fermentation continue, modern facilities regulate temperature and humidity with greater precision. This control ensures uniformity and refines flavor development. Some producers apply multiple fermentation cycles to refine the tobacco further.

2. Aging and Storage

Post-fermentation aging has transformed into a critical step. Tobacco leaves are aged in controlled environments, sometimes for several years, to mellow the tobacco and increase complexity. Aging rooms are equipped with technology to retain ideal conditions.

C. Contemporary Cigar Rolling

1. Machine-Made vs. Hand-Rolled Cigars

The 20th century witnessed the emergence of mechanization to cigar production. i thought about this Machine-made cigars apply homogenized tobacco leaf (HTL) binders and wrappers, enabling mass production at lower costs. However, premium cigars last to be hand-rolled, upholding the artisanal tradition.

2. Quality Control

Modern factories use strict quality control measures. This includes regular inspections, draw testing to ensure proper airflow, and sensory evaluations. Technology helps but does not replace the expertise of seasoned inspectors.

D. Innovations in Packaging and Distribution

Advancements in packaging materials safeguard cigars from environmental factors during shipping. Vacuum-sealed packaging, humidification devices, and sophisticated distribution logistics guarantee cigars reach consumers in optimal condition.

III. Comparing Past and Present Methods

A. Technological Advances

Technology has improved many aspects of cigar manufacturing without reducing the importance of skilled labor. Mechanization performs repetitive tasks, while artisans dedicate themselves on quality and craftsmanship.

B. Maintaining Tradition in a Modern Industry

Despite technological progress, the essence of cigar-making lasts rooted in tradition. Many producers highlight hand-rolled methods and traditional fermentation to copyright authenticity and cater to aficionados who admire heritage.

C. Challenges and Opportunities

The industry confronts challenges like regulatory changes, health concerns, and market fluctuations. However, opportunities present themselves from expanding global markets, premiumization trends, and consumer interest in artisanal products.

IV. The Art of Cigar Making: Preserving Craftsmanship

A. The Role of the Torcedor (Cigar Roller)

Torcedores are revered figures in cigar factories. Their expertise governs the cigar's construction and performance. Training to become a master roller can take years, demonstrating the complexity of the craft.

B. Apprenticeship and Skills Transfer

Many factories manage apprenticeship programs to teach skills to new generations. This affirms the survival of traditional techniques and preserves high standards in production.

C. Cultural Significance

Cigar-making is more than an business; it's the cultural heritage in regions like Cuba, the Dominican Republic, and Nicaragua. Festivals, museums, and tours observe this legacy, drawing enthusiasts worldwide.

The cigar manufacturing process is a captivating blend of time-honored traditions and modern innovations. While technology has incorporated efficiencies and consistency, the heart of cigar-making lies in the hands of skilled artisans who maintain a legacy that traverses centuries. Appreciating this journey boosts the appreciation of cigars, not just find more info as products but as personifications of cultural heritage and craftsmanship.

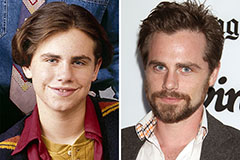

Rider Strong Then & Now!

Rider Strong Then & Now! Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now!